As the proportion of electric vehicles increases, so does the need for a powerful charging infrastructure. But how can electric vehicles be charged quickly, safely and efficiently using DC charging?

Basic information on how a charging station works and which technical principles need to be observed when it comes to charging technology is explained in detail in the section “How does a charging station for electric vehicles work?”.

Especially in public areas, DC charging is the key to fast and efficient charging and has long been indispensable for the nationwide supply of electric vehicles. Especially on long journeys, at highway service stations or when the car simply needs to be fully charged quickly in order to continue driving.

DC charging is required for charging powers above 22 kW. While AC charging (alternating current) is mainly used in the private sector, public DC charging enables high charging powers up to megawatt charging.

DC power electronics at the heart of a charging station: What is special about DC charging?

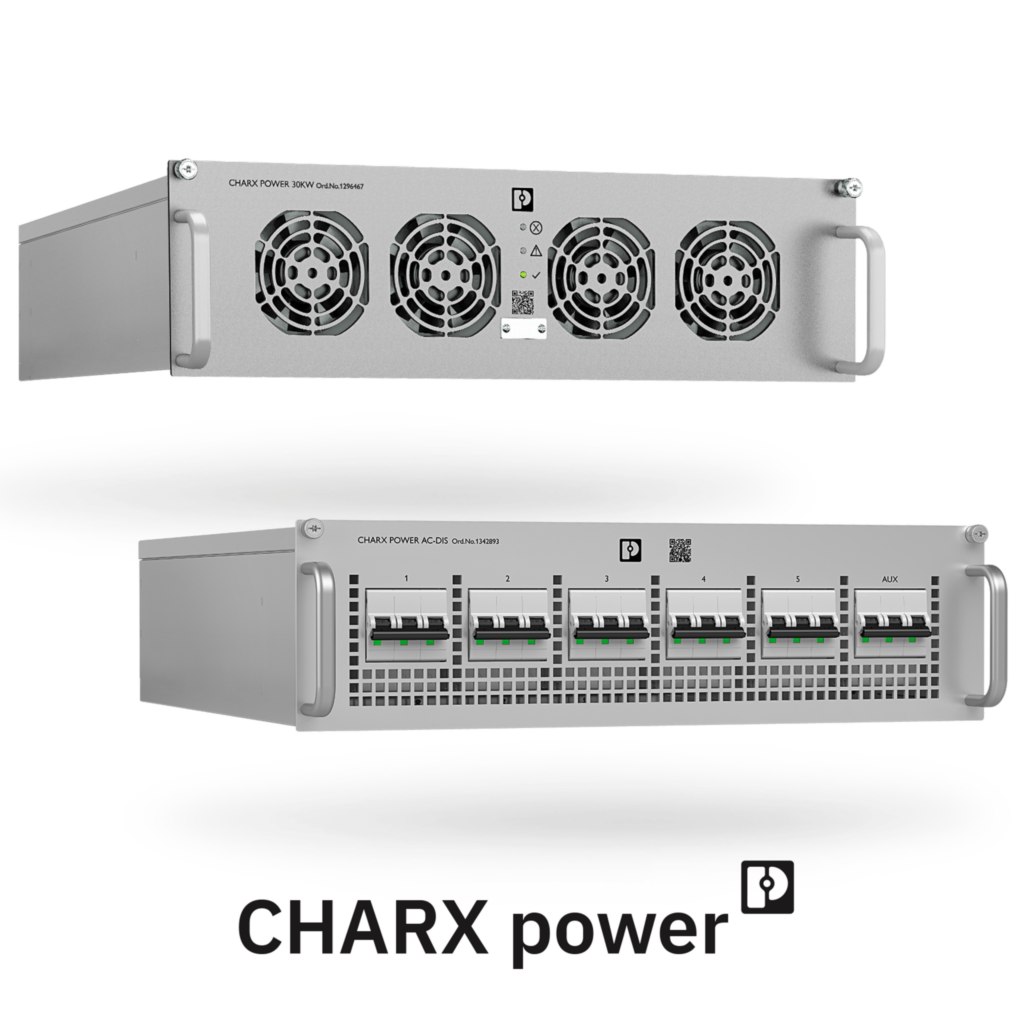

In contrast to AC charging, where the conversion from alternating current to direct current takes place in the vehicle, with DC charging the charging station takes on the task of conversion. The special feature and cost driver of DC charging is therefore the DC power electronics in the charging station: it converts the alternating current from the power grid into direct current and feeds it into the vehicle battery.

Like AC charging stations, DC charging stations have special power contactors that enable the safe switching of high charging currents. While lower charging powers are usually required in the private sector, significantly higher currents are used for DC fast charging stations in public spaces. DC power contactors are designed in such a way that they can reliably and safely interrupt the charging process in the event of residual currents or other faults. This ensures maximum safety when charging electric vehicles quickly and efficiently.

With the appropriate power electronics, DC currents can also be converted in addition to the classic AC mains current, i.e. DC current is already fed into the charging station and only the voltage level needs to be converted. A distinction is therefore made in power electronics between AC/DC modules and DC/DC modules. The high charging powers required can be achieved by interconnecting several power modules. Thanks to the standard 19-inch dimensions, the modules can be housed and installed either directly in the charging station or in a separate control cabinet, container or building.

Safety through permanently installed charging cables for public DC charging

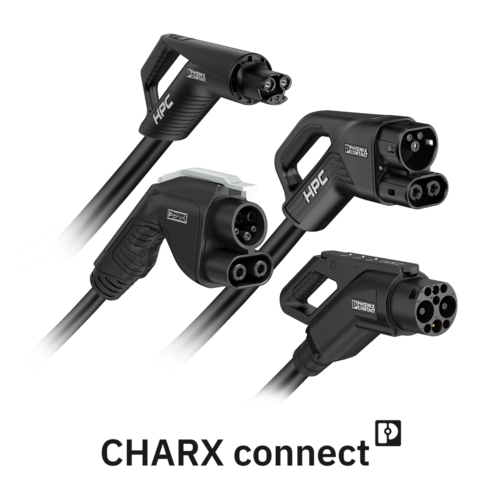

For safe and standard-compliant DC charging of electric vehicles, a permanently installed DC charging cable with a suitable charging connector is essential at every DC charging station. Modern DC charging cables ensure a reliable connection between the charging station and the electric vehicle and are also ergonomic, robust, durable and easy to maintain. According to current standards, a fixed installation of the DC charging cable on the charging station is mandatory due to the high DC currents, which is a decisive factor for maximum safety in the DC charging infrastructure. Connecting the vehicle via a mobile charging cable, as is the case with AC charging cables, is therefore not permitted by the standards for DC charging. Anyone planning or operating a DC charging station should ensure that they use high-quality, standard-compliant DC charging cables and plugs to ensure the smooth and safe operation of the charging infrastructure.

Safety and efficiency thanks to liquid-cooled charging connectors and monitoring during DC fast charging

Safety is the top priority in DC charging. Therefore, a fuse must be installed upstream of the power contactor to protect the charging process from overcurrents. In addition, high charging powers generate considerable heat due to the high current flow and environmental influences such as climate and solar radiation. Therefore, an HPC charging cable with integrated liquid cooling is technically necessary from 250-300 kW at the latest in order to avoid overheating.

A cooling unit installed in the charging station pumps environmentally friendly coolant, a mixture of water and glycol, through the HPC charging cable and connector. The temperature is measured via sensors on the power contacts and, if necessary, in the cable and on the microchip board in the plug.

An integrated leakage sensor also monitors the inside of the charging connector for any leaking coolant. The DC charging controller evaluates the status of the sensors and can thus optimally regulate the cooling capacity and ensure that the charging process is safely switched off in the event of leaks or overheating. Direct communication between the sensors and the controller increases system reliability and enables safe fast charging at high charging currents.

CCS charging inlets: Flexible DC charging for maximum compatibility

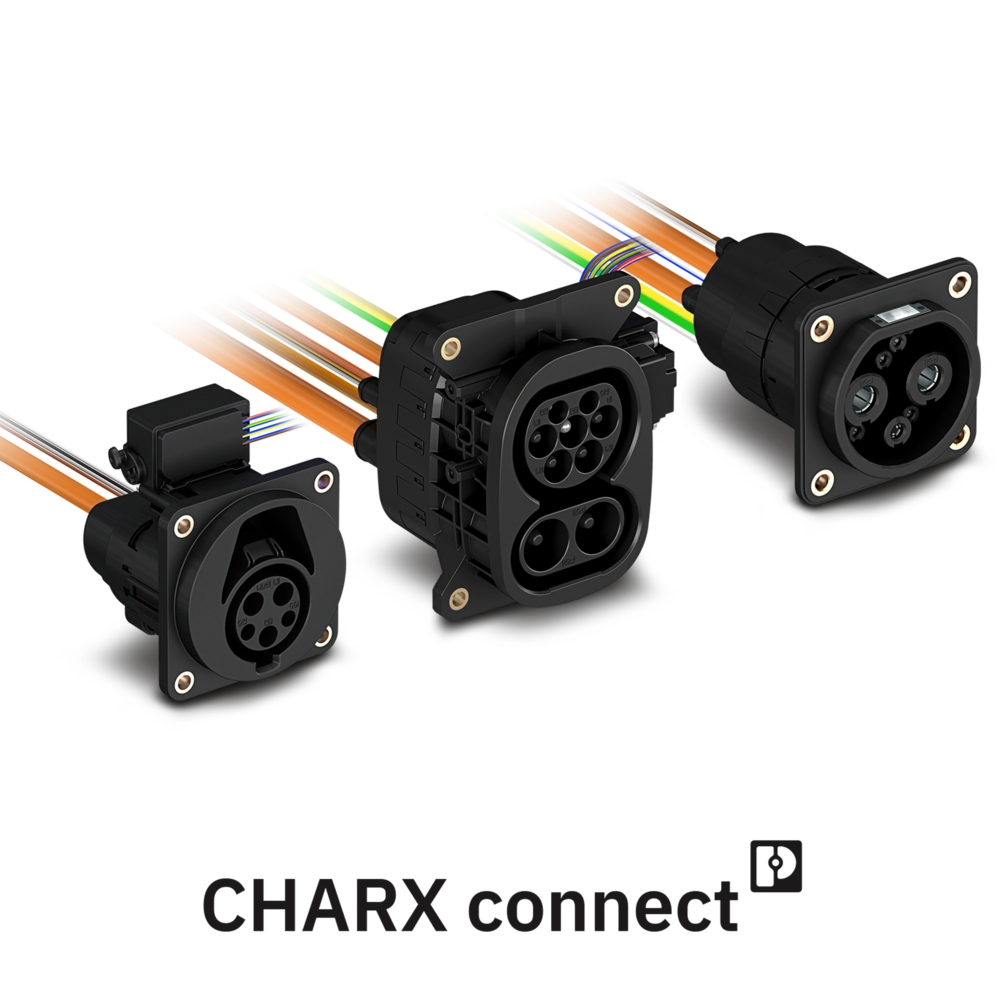

CCS charging inlets (Combined Charging System according to standard IEC 62196-3) are the established interface for charging electric vehicles, as they enable both AC charging and fast DC charging. With the two widely used standards CCS type 1 and CCS type 2, the upper area of the charging inlet and plug is used for both AC and DC charging, while the lower, special DC contacts are only used for DC charging.

This means that electric vehicles can be charged flexibly at AC charging stations in the private sector or at DC fast charging stations in public spaces using a single charging socket. Manufacturers of electric vehicles benefit from the fact that they only have to install one charging inlet in the vehicle: It saves installation space, reduces costs and increases compatibility with a wide variety of charging infrastructures worldwide.

In contrast, the Chinese GB/T standard requires separate charging sockets and plugs for AC and DC charging.

For the North American market, the North American Charging Standard (NACS) is becoming increasingly important and will replace the CCS Type 1 standard in the future. The switch to NACS , which – similar to CCS – enables AC and DC charging via a single interface, is therefore an important step for the expansion of the charging infrastructure and the further development of e-mobility in North America.

How does the charging current get into the electric vehicle? A clear explanation in the video.

FAQ

Häufig gestellte Fragen

What is DC charging and why is it faster than AC charging?

What safety standards apply to DC fast charging?

DC fast charging follows strict safety protocols such as ISO 15118 and IEC 61851. These standards ensure secure communication between the vehicle and the charging point, prevent overloads, and protect against electrical hazards. Modern DC charging stations also feature temperature monitoring and automatic shutdown to guarantee maximum safety for users and infrastructure.

What are the benefits of DC charging for charging infrastructure operators?

Operators benefit from shorter charging times, higher customer satisfaction, and improved site utilization. DC charging stations enable smart charging functions and load management, reducing operating costs and supporting grid stability. Additionally, they are future-proof, designed to accommodate upcoming vehicle models with higher charging capacities.

Discover situaible products now

Here you will find a selection of relevant products – based on the topics and recommendations from our blog post.