When it comes to the future of e-mobility, one term is being used more and more frequently: megawatt charging. It sounds like superlatives, like power, like the future – and like a technology that is set to change everything. But let’s be honest: do we really need it – or is CCS not enough?

To find out, we carried out charging tests together with a real heavyweight in the e-truck scene: EFORCE from Switzerland.

A practical report with EFORCE and Phoenix Contact e-mobility

EFORCE - Pioneers with Europe's first e-truck

E-Force One AG is no longer a newcomer in the field of e-mobility. Founded back in 2012, the company brought the first fully electric truck over 18 tons onto European roads in 2013. Today, the focus is on developing powerful drive trains for e-trucks. A team of four traveled all the way from Switzerland to join us at the All Electric Society Park (AES Park) at Phoenix Contact’s headquarters for a real endurance test with their latest electric truck.

The big charging test: CCS under full load

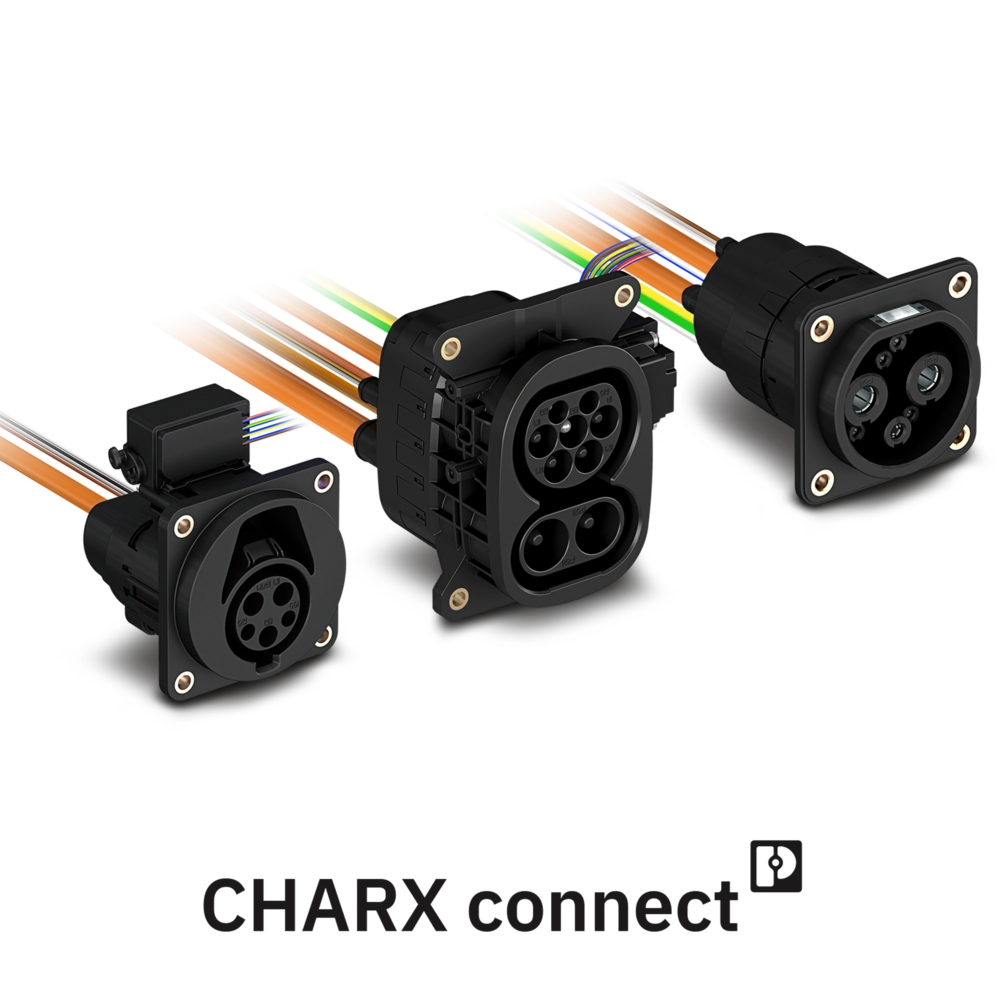

The aim was to put the e-truck’s charging system through its paces: From the battery to the charging controller to the CCS charging inlet from Phoenix Contact. The test was carried out on a DC charging station equipped with charging infrastructure components from Phoenix Contact.

And then the tension built up. Not a simulation, not a laboratory – but real conditions, real technology, real excitement.

- Start at 11 % SOC (state of charge), charged to 59 %

- 33 minutes charging time with a constant 500 amps

- Maximum charging power: 378 kW

- Steady increase in power over the entire charging process

We started at 11% SOC and charged up to 59% - all the time at 500 amps. That was our goal, and we achieved it. A really respectable result.

Jonas Berger, Product Manager at EFORCE

This outstanding result was made possible by the combination of our robust charging inlet and the new, liquid-cooled CCS megawatt HPC connector. The active cooling ensured that the high currents remained stable over the entire duration.

Charging test of the electric EFORCE truck

CCS - more than just a standard

CCS is not just an established standard – it is a reliable companion for everyday e-mobility. But how far does this solution really go? Are there areas of application where CCS reaches its limits?

Yes – for example in long-distance transportation with extreme range requirements, in shipping or in mining. The Megawatt Charging System (MCS) was developed for such scenarios, enabling charging powers of up to 3.75 MW – ideal for vehicles with very large batteries and narrow time windows.

But our joint test with EFORCE shows: CCS is completely sufficient for many e-vehicles, mobile machines and even for regular long-distance transportation.

The Megawatt Charging System is primarily needed for trucks that drive long distances and are really involved in long-distance transport. Otherwise you would have to install such a high battery capacity that the vehicle would become far too heavy.

Jonas Berger, Product Manager at EFORCE

And if more power is needed? Then it’s already there. With our new CCS megawatt connector with active liquid cooling, up to 1,000 kW charging power can be realized – without any costly grid expansion. A solution that already works today and enables a seamless transition to the next generation of charging.

Conclusion: Sometimes the best solution is already there

It’s not always the biggest number that makes the difference. Sometimes it’s the well thought-out, practical solution that really makes the difference. Our joint day with EFORCE showed that CCS is not just a standard. It is a solution. For today. For tomorrow. For real applications.

The best thing is: The CCS system already exists - it just needs to be used.

Stefan Staiber, System Consultant at Phoenix Contact Switzerland

FAQ

Frequently asked questions

What is the difference between CCS and MCS?

Is CCS sufficient for long-distance transport or do you need Megawatt-Charging?

When does it make sense to use Megawatt-Charging?

Discover suitable products now

Here you will find a selection of relevant products – based on the topics and recommendations from our blog post.