At first glance, construction sites and agricultural barns may seem like completely different work environments. Yet both sectors are undergoing a similar transformation: increasing demands for sustainability, efficiency, and healthy working conditions are shaping both industries. Electric utility vehicles offer a forward-looking solution that not only excels ecologically but also proves economically and practically beneficial in everyday use.

The potential of this technology becomes especially clear in noise- and emission-sensitive work environments such as indoor construction sites. This is where compact, articulated electric loaders from Avant Tecno can be deployed.

Avant Tecno, a globally leading manufacturer from Finland, specializes in compact articulated loaders and versatile special attachments. With over 90,000 machines produced, sales companies in the USA, Brazil, Germany, and the UK, and exports to more than 70 countries, Avant stands for quality, innovation, and global reach. The fully electric Avant e series was developed for noise- and emission-sensitive work environments, enabling nearly silent and clean operation – ideal for indoor use, livestock barns, or municipal applications.

The Demands of Indoor Construction Sites

Indoor construction sites place special demands on people and machinery. Whether during renovations, expansions, or the construction of industrial halls, working with machines in enclosed spaces requires solutions that are emission-free, quiet, and efficient. Electric vehicles deliver on all fronts: they reduce noise levels, improve air quality, and create a healthier working environment for everyone involved. A vivid example is the use of electric excavators on indoor construction sites, as successfully demonstrated by Avant.

Typical applications include transporting building materials within enclosed structures, supplying assembly points and workstations, and operating in particularly sensitive environments. These include hospitals or schools, where noise control and clean air are top priorities – especially when construction work takes place during ongoing operations.

Electric compact loaders or transporters with AC charging infrastructure are ideal for scheduled operations with fixed charging times. Their integration into existing energy management systems is also simple and cost-effective.

The Barn as a High-Tech Workplace

In agriculture – especially in barn operations – unique requirements apply, as animals are sensitive to noise and exhaust fumes. Diesel-powered machines can cause stress, degrade air quality, and even negatively affect animals’ feeding behavior.

Electric utility vehicles offer significant advantages over combustion engine vehicles: they operate very quietly, minimizing disturbance to animals, and emit no local emissions, preserving air quality in the barn.

Their compact design makes them ideal for narrow aisles and low ceilings commonly found in barn facilities. Their multifunctionality allows various tasks – such as feeding, mucking out, or transporting materials – to be handled with a single machine. In automated or semi-automated barn systems, electric machines play a key role in modern livestock management, as operators increasingly rely on this technology to efficiently clean barns, distribute feed, or maintain riding arenas.

Electric utility vehicles are also gaining popularity in landscaping. They are particularly useful in parks and urban green spaces, where traditional machines are often unwelcome due to noise or emissions.

The Charging Technology Behind It: AC Inlets from Phoenix Contact

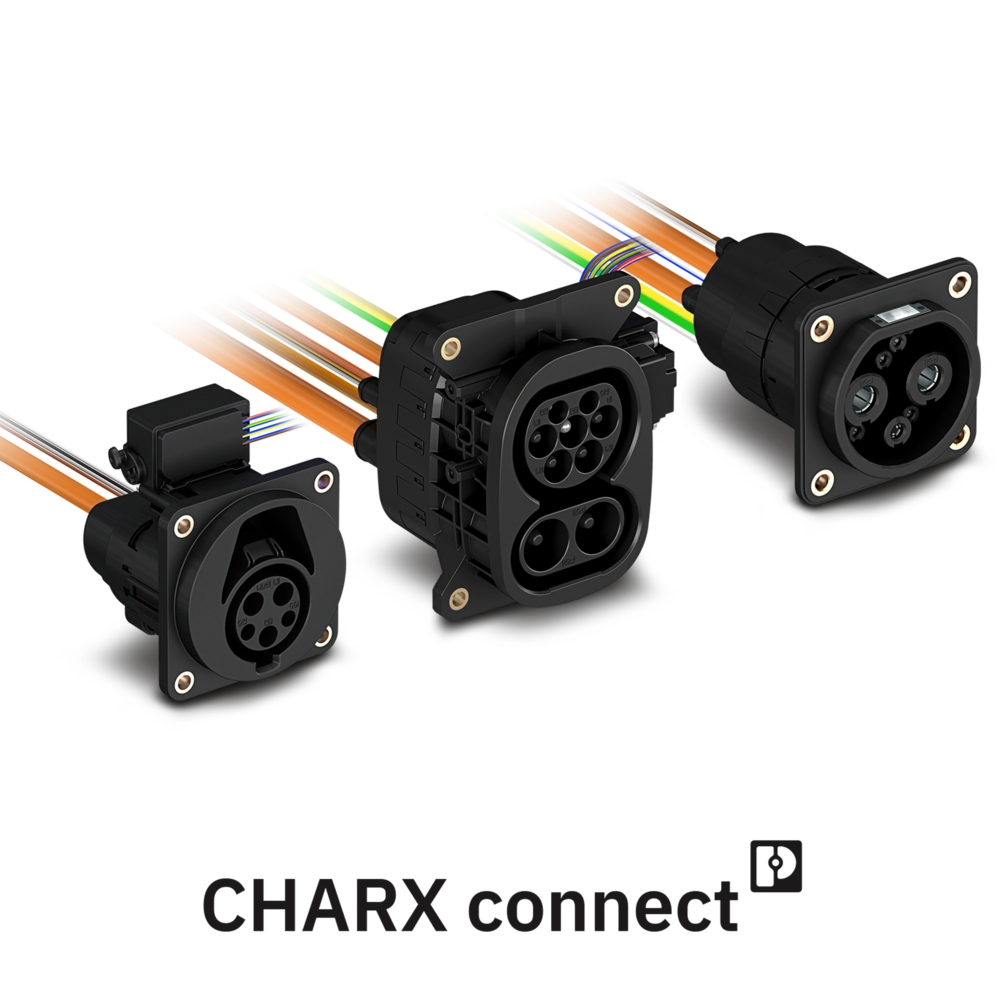

Avant has deliberately chosen AC inlets from Phoenix Contact for electrifying its loaders. The key factors were high reliability, robust design, and easy integration into the overall system – crucial for ensuring smooth and safe operation even under demanding conditions.

To ensure electric utility vehicles operate reliably, robust and intelligent charging infrastructure is essential. Phoenix Contact offers AC inlets specifically developed for use in utility vehicles.

Technical Highlights:

- Type 2 with 32 A charging current and up to 22 kW charging power

- Type 1 with 48 A or 80 A charging current and up to 20 kW charging power

- Locking actuator for secure connection during charging

- Integrated temperature sensors

- IEC 62196-2 and SAE J1772 compliant

Thanks to high IP protection ratings (IP6K7 and IP6K5) and additional protection in the plug area (IP6K9K and IP6K6K), the AC inlets are ideally suited for harsh environments with dust, moisture, or mud. They offer comprehensive protection against dust and water, withstand high-pressure and steam jet cleaning, and ensure safe touch protection.

Energy Autonomy and Sustainability

A key aspect of future-proof charging infrastructure is energy autonomy and sustainability. Especially in agriculture, combining electric vehicles with renewable energy is a real game-changer. Many farms already use photovoltaic, biogas, or wind power systems. This allows electric utility vehicles to be powered by solar energy during the day and efficiently charged via AC infrastructure at night.

Looking ahead, the potential for bidirectional grid integration – known as Vehicle-to-Grid (V2G) –opens up new possibilities. It not only helps reduce energy costs but also significantly increases independence from fossil fuels.

Looking Ahead: Digitalization and Smart Fleets

The next evolutionary step for electric utility vehicles lies in their digital connectivity. Through digital fleet management, predictive maintenance, and intelligent charging planning, operational efficiency can be significantly increased. System integrators and vehicle manufacturers benefit by optimizing charging cycles, analyzing operational data, and automatically adjusting maintenance intervals.

Modern electric utility vehicles, thanks to connectivity and digitalization, open up entirely new possibilities: they integrate seamlessly into existing process chains, support automated workflows, and offer unprecedented transparency in fleet management through remote maintenance and data analysis. Intelligent charging planning and integration into operational energy systems make them an active part of smart business structures, promoting efficiency, reliability, and profitability.

Thus, electric vehicles today are far more than just an ecological alternative. They are becoming a driving force for productivity, innovation, and sustainable success across various industries.

Conclusion: One Vehicle, Many Possibilities

Whether on construction sites or in barns, electric utility vehicles are far more than just an ecological alternative. They boost productivity, improve working conditions, and make a significant contribution to corporate sustainability goals.

With electric solutions like Avant loaders and high-quality components such as Phoenix Contact’s AC inlets, operators benefit not only from sustainable technology but also from productivity, flexibility, and optimal investment protection – regardless of industry or application.

FAQ

Frequently asked questions

What are the advantages of electric commercial vehicles on construction sites?

Electric commercial vehicles help reduce emissions, lower operating costs, and operate much more quietly than diesel-powered alternatives. This makes them perfect for urban construction sites and noise-sensitive areas. Phoenix Contact provides robust charging solutions designed specifically for demanding environments.

How does the charging infrastructure for electric commercial vehicles work in agriculture?

Agricultural operations require flexible and weatherproof charging systems. Phoenix Contact offers solutions that can be installed both indoors, such as in barns, and outdoors. With high charging capacity, vehicles are quickly ready for use, ensuring maximum uptime.

What challenges exist when charging commercial vehicles on construction sites?

Construction sites often face harsh conditions like dust, moisture, and unstable power sources. Mobile and durable charging points are essential. Phoenix Contact develops IP-rated components and smart load management systems to ensure reliable charging even in tough environments.

Discover situaible products now

Here you will find a selection of relevant products – based on the topics and recommendations from our blog post.