The electrification of heavy-duty vehicles is on the brink of a new era. Electric commercial vehicles such as e-buses, e-trucks, construction machinery, and heavy municipal and special-purpose vehicles are no longer visionary concepts—they are already part of everyday operations. They perform mission‑critical tasks in transport, logistics, construction, waste management, and municipal applications.

As driving ranges increase, energy demand grows, and availability requirements rise, pressure on vehicle architectures intensifies. Every component must become smarter, more compact, and more robust.

Manufacturers face a fundamental question: how can the growing complexity of the electric drivetrain be managed without making vehicles larger, heavier, or more maintenance‑intensive? The answer lies in a place that has long been underestimated – the inlet, the interface between the vehicle and the charging infrastructure.

With global demand for ever higher charging power, it is becoming clear that the CCS vehicle inlet (Combined Charging System) must be more than a mechanical power transfer point. It is evolving into the intelligent heart of the charging process and marks the beginning of a paradigm shift.

Why the CCS Inlet Must Deliver More Than Ever Before

The Combined Charging System (CCS) is firmly established worldwide, especially in the heavy‑duty segment. As charging power increases and vehicles become more connected, the requirements placed on the charging interface continue to grow.

The Challenge of Increasing Charging Power

Heavy-duty vehicles require short downtimes, maximum availability, and high energy throughput. High Power Charging (HPC) with up to 800 A is now a key prerequisite for applications such as depot and opportunity charging of e‑buses, long‑haul trucks using megawatt charging, construction and municipal vehicles with intensive duty cycles, and system integrators supporting flexible vehicle architectures.

However, higher currents mean thicker cables, larger cross‑sections, sophisticated cooling or temperature monitoring, and increasingly complex control and communication structures.

Why Traditional Architectures Are Reaching Their Limits

Traditionally, a high‑power charging system consists of multiple separate components: the CCS inlet, a standalone DC charging controller (EVCC – Electric Vehicle Charging Controller), complex wiring harnesses, and various interfaces with separate power and communication logic.

This architecture introduces several challenges:

Challenge

Effect

- Many individual components

- Complex wiring

- Large installation space

- Multiple suppliers

- Low modularity

- High integration effort

- Increased risk of failure

- Limited freedom in vehicle design

- High coordination effort and risk

- Long development cycles

Manufacturers report integration phases lasting several months – solely due to interface and software coordination between the inlet, EVCC, and vehicle control unit (VCU). This results in high costs, long development timelines, and unnecessary complexity.

The Solution: Bringing Control Where It Belongs – Directly into the Inlet

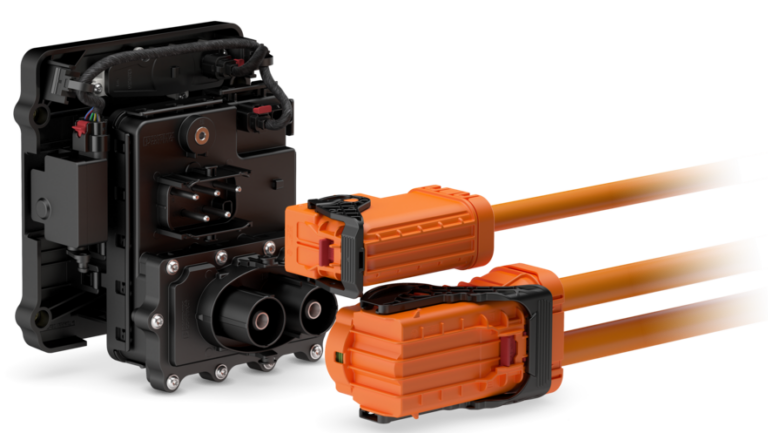

With CHARX connect advanced , a new category of high‑power charging interfaces emerges: a CCS inlet with integrated intelligence. The mechanical vehicle inlet and the complete DC charging control are combined into a single unit.ung verschmelzen zu einer Einheit

One Component Instead of Two – A Game Changer

In this new system architecture, no separate DC charging controller is required. Complex wiring is eliminated, all protocols are fully integrated, and mechanics, electronics, and software come from a single source. PLC communication is processed directly inside the inlet, significantly reducing integration risks.

The intelligence of the charging process is located exactly where it makes the most sense: directly in the inlet.

Wie integrierte Steuerung Bauraum spart

A standalone EVCC requires its own housing, mounting points, wiring paths, EMC shielding, and protection against vibration and environmental influences. Eliminating this component results in substantial savings: several liters of installation space, reduced material and weight, and fewer interfaces that need protection. For manufacturers, this means greater freedom in vehicle architecture design.

Less Complexity, More Robustness – A System Architecture Leap for OEMs

Easy Integration with Validated Systems

Because control and inlet are combined in one component, communication between them is perfectly aligned. Integration on the vehicle side is reduced to a CAN interface (Controller Area Network), a limited number of defined signals, clear software APIs (Application Programming Interfaces), and a unified diagnostic and service environment.

Vehicle manufacturers and system integrators no longer need to handle PLC communication (Power Line Communication), as this is fully managed by the integrated charging controller within the inlet. The result: reduced development effort, lower risk, and fewer surprises during validation.

Reduction of Error Sources

Typical failure points of conventional systems are eliminated: communication issues between inlet and EVCC disappear, EMC interference is significantly reduced, software mismatches between controller and mechanics are avoided, and incorrect wiring or cable length issues are eliminated through modular connectors.

Fewer Suppliers = Less Coordination Effort

For manufacturers, this represents a major advantage: one point of contact, one development cycle, one certification process, one documentation source, and a unified quality management system. This leads to faster approvals, lower costs, and reduced risk across the entire product lifecycle.

How Integrated Control Opens New Possibilities for Vehicle Design

Flexible Mounting Locations Through a Compact Design

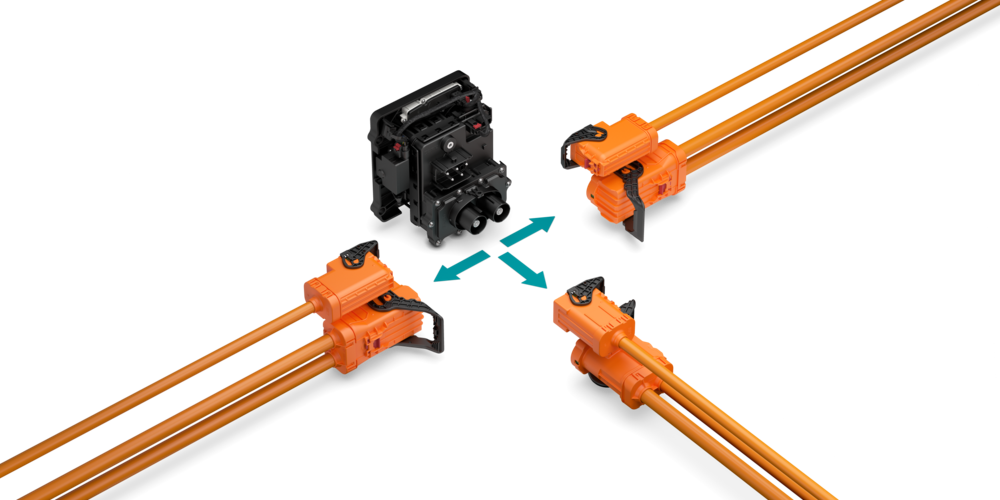

Integrating the control unit eliminates the need for a standalone EVCC. The inlet features a compact design and modular cable exit options. Cable routing can be configured as 90° left, 90° right, or straight.

This enables integration into a wide range of vehicle platforms, such as tight front sections of city buses, highly loaded truck frames, modular power‑unit trays in construction machinery, or side access panels in municipal vehicles.

Vereinfachte Wartung durch trennbares Inlet

Plug‑in HV cables allow tool‑free separation of the inlet from the wiring. In maintenance cases, the inlet or HV cables can be replaced easily – without opening the cooling system, removing large assemblies, or using special tools.

For operators, this means higher availability, shorter workshop times, and lower total cost of ownership. System integrators benefit from structured replacement processes, predictable spare‑parts concepts, and reduced fleet maintenance complexity.

Technical Capabilities That Enable New Use Cases

800 A Boost Mode – Ready for High Power Charging (HPC)

With up to 800 A, the integrated inlet enables ultra‑fast charging for depot‑based e‑buses, long‑haul trucks, and off‑road machines with large battery capacities. This meets current HPC requirements and prepares manufacturers for future power increases.

Future‑Proof Through Standards and Safety Compliance

The integrated control complies with standards such as ISO 15118, DIN 70121, VDV 261 (for buses), ASIL B according to ISO 26262, and preparations for UNECE R155/R156 (cybersecurity). This allows seamless integration into modern vehicle architectures – whether bus, truck, or heavy‑duty vehicle.

Why Integrated Control Is the Future of Heavy Duty E-Mobility

Heavy‑duty mobility demands solutions that are robust, scalable, efficient, future‑proof, and service‑friendly. Integrating control electronics directly into the inlet creates a new class of charging systems that combines all of these requirements.

Key benefits at a glance:

- Saves installation space

- Reduces complexity

- Simplifies assembly

- Minimizes interfaces

- Lowers development costs

- Simplifies service

- Enables high-current charging

- Ensures future compliance with standards

This combination makes integrated inlet systems one of the most promising trends in commercial electric vehicle architectures.

Conclusion: The Transformation Begins at the Inlet – Now Is the Time to Innovate

The electrification of heavy‑duty vehicles presents manufacturers with both major challenges and significant opportunities. The shift from separate to integrated charging interfaces is comparable to earlier technological leaps in drivetrain and control electronics.

What is considered innovation today will soon become the industry standard. Integrated CCS inlets with intelligent control are more than a technological upgrade—they form a new foundation for faster charging, more efficient designs, lower lifecycle costs, easier integration, and higher reliability.

For bus manufacturers, truck OEMs, and system integrators, this means: now is the ideal time to plan this technology into new platforms and secure a decisive competitive advantage.

FAQ

Frequently asked questions

Why does the CCS charging inlet have to do more today than in the past?

The CCS charging inlet is no longer just a mechanical power transfer point. Due to increasing charging powers, higher currents and increasing vehicle networking, the demands on the charging interface are growing faster than classic vehicle architectures can keep up. This is why the inlet is becoming the intelligent heart of the charging process.

are the advantages of a CCS charging inlet with integrated control?

The integration of the entire DC charging controller in the inlet eliminates the need for an external EVCC controller, complex cabling and potential sources of error. Mechanics, electronics and software come from a single source, PLC communication is processed directly in the inlet – this significantly reduces effort, costs and risks.

How do vehicle manufacturers benefit from a CCS charging inlet with integrated control and why is this charging interface future-proof?

Manufacturers receive a validated, easy-to-integrate system: just one CAN interface, few signals, clear APIs and a standardized diagnostic environment. Development times are also reduced, as typical sources of error such as EMC interference or communication problems are eliminated and only one supplier is required.

Discover suitable products now

Here you will find a selection of relevant products – based on the topics and recommendations from our blog post.